Key Benefits:

2mm material thickness as standard

Saw cut into floor 20mm giving a better seal to floor on completion

Can be made to suit existing floors and walls removing need to change floor surfaces

Cleaning:

Routine cleaning is highly recommended to preserve and maintain the integrity of the surface. Stainless steel is easily cleaned by many different methods. Frequently using warm water with a mild detergent would suffice. For more cleaning information please refer to MCES Material Cleaning Guide.

Site Installation:

MCES offer a full site installation including saw cutting of the floor, fully welded and polished joints. Filling of the kerbs using C30 concrete or non-shrink grout. Sealing of the kerbs to existing resin floors using Resujoint.

Maintenance:

Regular checks for any build up of dirt or fluids that may cause corrosion.

Technical Information:

Available in 304 or 316 stainless steel

2mm or 3mm Dull polished finish

Fully Welded

C30 concrete infill

M12 through bolts fixings

Product Information:

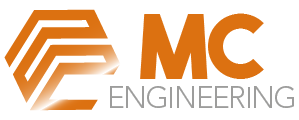

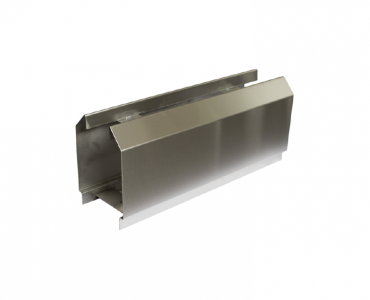

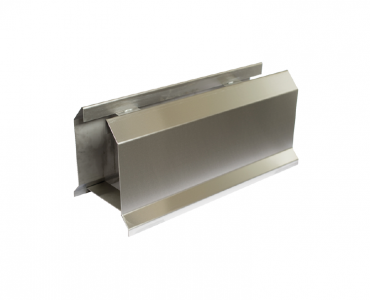

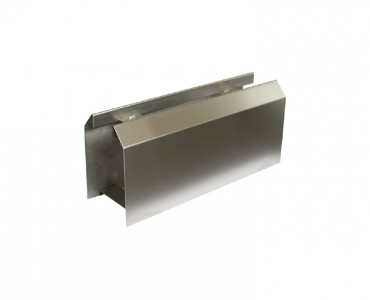

The standard Solo Kerb is designed support the composite wall panels.

An ideal product for creating an hygienic barrier between the wall and the floor in places such as food factories and other industrial buildings, where a high level of hygiene is critical.

Size A, B, C and D can all be custom made to suit each individual customer’s requirements.

The following document details the general cleaning procedures for all MC Engineering Stain steel products unless instructed otherwise

Stainless steels need to be cleaned for aesthetic considerations and to preserve corrosion resistance. Stainless steel is protected from corrosion by a thin layer of chromium oxide. Oxygen from the atmosphere combines with the chromium in the stainless steel to form this passive chromium oxide film that protects from the further corrosion. Any contamination of the surface by dirt, or other material, hinders this passivation process and traps corrosive agents, reducing corrosion protection. Thus, some form of routine cleaning is necessary to preserve the appearance and integrity of the surface. Stainless steels are easily cleaned by many different methods. They actually thrive with frequent cleaning, and, unlike some other materials, it is impossible to “wear out” stainless steel by excessive cleaning. The effect of surface/pattern roughness, grain/pattern orientation, and designs that allow for maximum rain cleaning (exterior applications) should be considered.

Types Of Surface Contaminants:

Dirt – Like any surface that is exposed to the environment, stainless steel can get dirty. Dirt and soil can consist of accumulated dust and a variety of contaminates that come from many sources, ranging from the wind to everyday use. These contaminates will vary greatly in their effect on appearance and corrosivity and ease of removal. While some may be easily removed, others may require specific cleaners for effective removal. It may be necessary to identity the contaminate or experiment with various cleaners. Frequently, warm water with or without a gentle detergent is sufficient. Next in order are mild non-scratching abrasive powders such as typical household cleaners. These can be used with warm water, bristle brushes, sponges, or clean cloths.

Ordinary carbon steel brushes or steel wool should be avoided as they may leave particles embedded on the surface which can lead to RUSTING.

For more aggressive cleaning, a small amount of vinegar can be added to the scouring powder.

Cleaning should always be followed by rinsing in clean hot water.

When water contains mineral solids, which leave water spots, it is advisable to wipe the surface completely with dry towels.

Fingerprints and Stains – Fingerprints and mild stains resulting from normal use in consumer and architectural applications are the most common surface contaminates. Fortunately, these usually affect only appearance and seldom have an effect on corrosion resistance. They are easy to remove by a variety of simple cleaning methods. Fingerprints are probably the most troublesome marks to remove from the surface of smooth polished or bright finished stainless steel. Fortunately, they can be removed with a glass cleaner or by gentle rubbing with a paste of soda ash (sodium carbonate) and water applied with a soft rag. Once again, this should be followed by a thorough warm water rinse. There are several special surface finishes where fingerprints present special problems: polished No. 6, etched, some abrasive blasted finishes, and light electrochemical colours applied over satin or brushed finishes, (NOTE: there are several special finishes designed to withstand fingerprints: embossed, swirl patterns, lined patterns, etc).

Oil and Grease – Workshop oils, which may contain grease, grit and metal chips, commonly produce surfacing soiling after many shops operations. Greases and other contaminates may also soil surfaces in food preparation and many other household and commercial situations. These soils may be corrosive in themselves or may not allow the surface to maintain passivity, and so periodic removal is a necessity. Initially, soap or detergent and water may be tried or a combination of detergent and water plus a solvent. The removal of oil and grease from stainless steel parts by immersion in chemical solvents is frequently used with cold-formed or machined parts that are laden with lubricants. This process, in its simplest form, consists of bringing liquid solvent into contact with the surface to be cleaned and allowing dissolution to take place; for example, washing a surface with trichloroethylene or similar liquid or stirring a batch of small parts in a container of solvent. Non-Halogenated solvents, such as acetone, methyl alcohol, ethyl alcohol, methyl ethyl ketone, benzene, isopropyl alcohol, toluene, mineral spirits, and turpentine work well. Many of these solvents are widely used as individual cleaners, but there are thousands of blended or compound cleaners on the market. Users are advised to contact suppliers of solvents for information on their applications on stainless steel.

Types of Cleaners and Methods:

General Precautions:

In selecting cleaning practices, consider the possibility of scratching and the potential for post-cleaning corrosion caused by incompletely removed cleaners. Scratching can occur on a bright mirror finish by cleaners that contain hard abrasives, or even by “grit” in wash water. this is usually not a problem on dull finishes, or those surfaces finished with a coarse polishing grit. The best preventative measure is to avoid using abrasive cleaners unless absolutely necessary. when abrasives are needed, first experiment on an inconspicuous area. A “soft abrasive,” such as pumice, should be used. Abrasives can permanently damage some coloured and highly polished finishes. Advice should be obtained from the finish supplier when cleaning special finishes. Many cleaners contain corrosive ingredients which require thorough post-clean rinsing with clean water; however, thorough rinsing is recommended for all cleaning procedures.

Clean Water and Wipe – The simplest, safest and least costly method that will adequately do the job is always the best method. Stainless surfaces thrive with frequent cleaning because there is no surface coating to wear off stainless steels. A soft cloth and clean warm water should always be the first choice for mild stains and loose dirt and soils. A final rinse with clean water and a dry wipe will complete the process and eliminate the possibility of water stains. Solvent Cleaning – Organic solvents can be used to fresh fresh fingerprints and oils and greases that have not had time to oxidise or decompose. There are many compounded or blended organic cleaners that are commercially available and attempt to optimise both clean-ability and safety attributes. Cleaning can be accomplished by immersing smaller articles directly into the solvent, wiping with solvent-impregnated cloths, or by sophisticated vapour or spray methods. The wiping technique sometimes leaves a streaked surface.

Household Cleaners – Household cleaners fall into two categories: detergent (non-abrasive) and abrasive cleaners. Both are effective for many mild dirt, stain, and soil deposits, as well as light oils such as fingerprints. The abrasive cleaners are more effective but introduce the possibility of scratching the surface. However, the degree of abrasiveness will vary greatly with the particular product, and some brands will produce noticeable scratching on only the most highly polished and some coloured surfaces. All of these cleaners vary widely with respect to their acidity and the amount of chloride they contain. A neutral cleaner low in chloride is preferred unless the user is assured that the surface can be thoroughly rinsed after cleaning. The fact that the label states “for stainless steel” is no guarantee that the product is not abrasive, not acidic, or low in chloride. The cleaning method generally employed with these cleaners is to apply them to the stainless surface and follow by cloth wiping, or to wipe directly with a cleaner-impregnated soft cloth. In all cases the cleaned surface should be thoroughly rinsed with clean water and wiped dry with a soft cloth if water streaking is a consideration.

Commercial cleaners – Many commercial cleaners compounded from phosphates, synthetic detergents, and alkalis are available for the cleaning severely soiled or stained stainless surface. When used with a variety of cleaning methods, these cleaners can safely provide effective cleaning. Manufacturers should be consulted and their recommendations followed whenever using cleaners of this kind. The general precautions stated above also pertain to these cleaners.

Care of Stainless Steel

The cleaner stainless steel can be kept while in storage, being processed or during use, the greater the assurance of optimum corrosion resistance. Some tips on the care of stainless steel are listed below:

- Use paper or other protective wrapping on the surface of the stainless steel until processing is complete

- Handle stainless steel with clean gloves or cloths to guard against stains or finger marks.

- Avoid the use of oily rags or greasy cloths when wiping the surface

- Do routine cleaning of exposed surfaces. Buildings with window washing systems can utilise this method to clean exterior panels.

- Where possible, after cleaning rinse thoroughly with water.

- Cleaning with chloride-containing detergents must be avoided.

- Event the finest cleaning powders can scratch or burnish a mil-rolled finish. on polished finishes, rubbing or wiping should be done in the direction of the polish lines, NOT across them.

- DO NOT USE SOLVENTS in closed spaces or while smoking

*Many adhesive-backed papers and plastic sheets or tape applied to stainless steel for protection “age” in fairly short periods of time and become extremely difficult to remove.

Manufacturers should be contacted regarding information as to how long protective films or paper can be left in place.